this post was submitted on 24 Sep 2024

37 points (100.0% liked)

Ask Electronics

3351 readers

2 users here now

For questions about component-level electronic circuits, tools and equipment.

Rules

1: Be nice.

2: Be on-topic (eg: Electronic, not electrical).

3: No commercial stuff, buying, selling or valuations.

4: Be safe.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

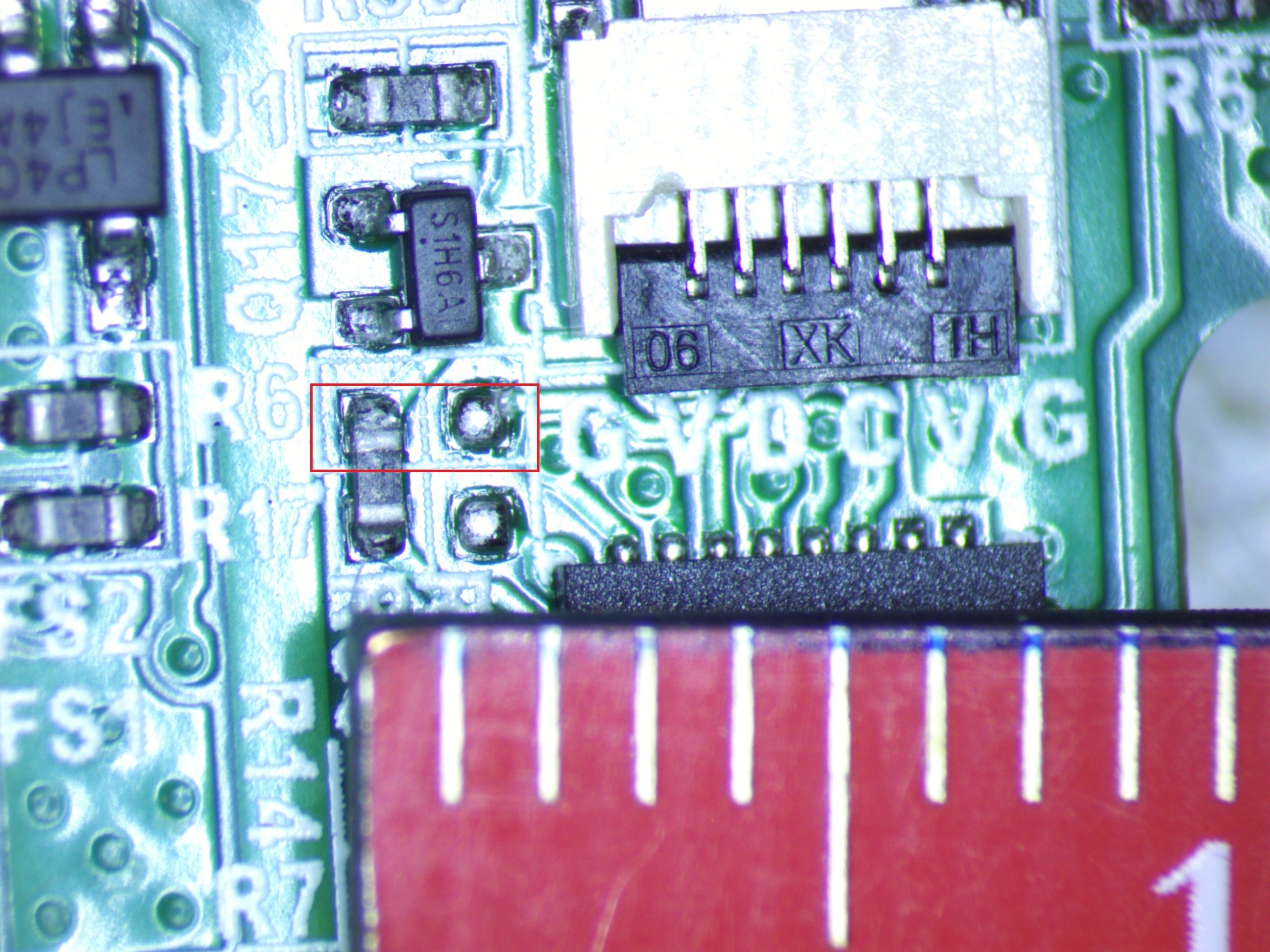

If i didn't have a soldering iron, I'd probably grab a diode or resistor leg, snip it just enough to bridge the gap, press it down on the contacts, use super glue to hold it in place on both sides and the middle until it held and hope the glue doesn't block the contacts.

But this is an extremely shoddy solution and i doubt it will last long. You have to hold it firmly in place or the glue will get underneath the component leg. The user can't let it roll around under the finger. I suggest pressing it against the upper side of the contacts in the picture for leverage. Try it out yourself and see if you can do it. Once you verify with a multimeter you get current through, you can apply more super glue on top between the contacts to give it a little more grip, that may make it hold on for longer. Since it's for a low current application I'm betting just the contact surface of the component leg with the solder blobs underneath will be enough and will not overheat, but i would suggest letting it run a bit just to make sure. You can always make it just a smidge longer in order for the component leg to wrap around the blobs to increase the contact surface, in sort of a C shape.

A soldering iron for students can be pretty cheap and I'm only suggesting this alternative so you have some sort of low cost solution that doesn't involve one. Any diode or resistor will do, really, for like 5 cents and superglue for like 2/3€. Or if you want to put it in a kit just send small snips of tin plated, copper clad steel wire, but depending on how many kits you are manufacturing, it might be more cost effective just to use resistor/diode legs harvested from stuff you've got lying around.