this post was submitted on 24 Sep 2024

37 points (100.0% liked)

Ask Electronics

3351 readers

2 users here now

For questions about component-level electronic circuits, tools and equipment.

Rules

1: Be nice.

2: Be on-topic (eg: Electronic, not electrical).

3: No commercial stuff, buying, selling or valuations.

4: Be safe.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

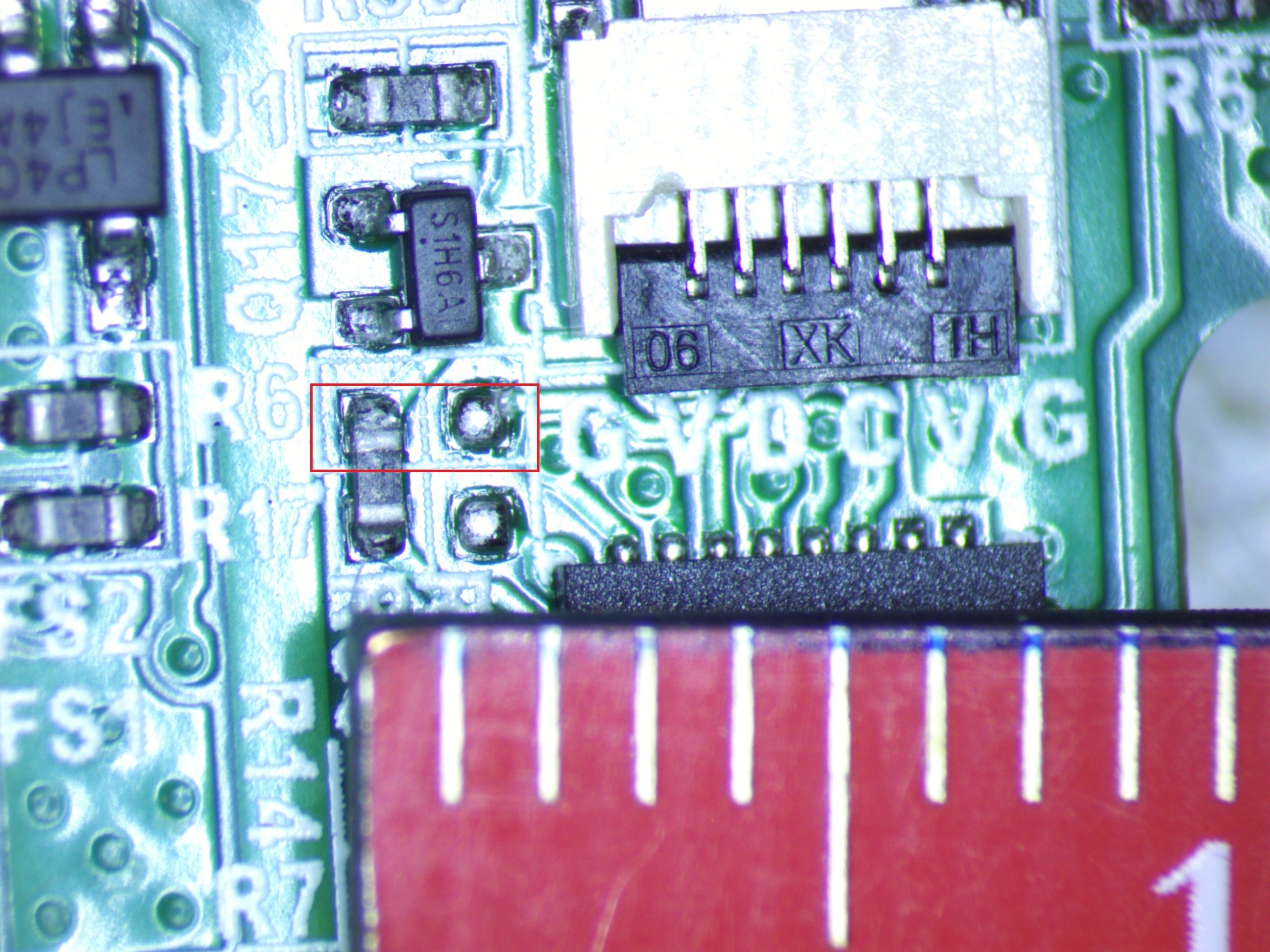

Looks like a basic soldering job, give it a touch with resin and fresh solder and create a blob. Even my non-technical grandpa (in his 30s, he needed his 3yo daughter to operate a cassette deck for him!) had a soldering iron for some reason in his shack, and it's a good skill to have.

I'd need measurements or a better picture but it looks like they might be connected to adjacent pins (3 and 4, where 1 is on the right side from our POV) on the FFC connector. I would try to target that first, there are several options if that is available:

Speaking of the last method, you might not need a board edge nearby if you can rely on pressure from the device's housing:

If applicable, remind them that when screwing screws back into plastic, it is necessary to twist counterclockwise first to locate the original thread and not make a new one, which could ruin it.