57

Cutting board questions

(lemmy.world)

A handmade home for woodworkers and admirers of woodworkers. Our community icon is a planter box made by @Captain Aggravated, the winner of our summer '24 woodworking contest. Congratulations!

The only reason why cutting boards are often thin is cost. A thicker cutting board will be more resistant to warping. I encourage using thicker pieces.

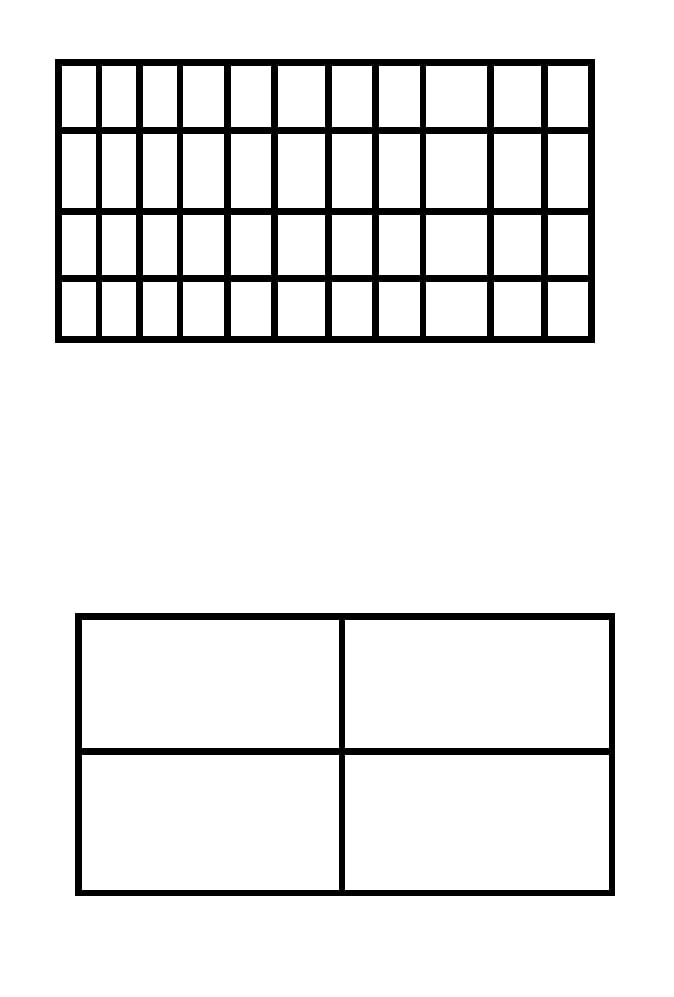

I don't think I'm describing my question clearly. I'm imagining a 2" thick cutting board made up of 4, 6"×12" end grain slices from the beam.

Every end grain cutting board I've ever seen is comprised of many individual pieces from like .5"×.5" up to like 2"×2" at the largest.

Is checking the only risk from using very large pieces, like I want to?

Oh, I haven't got a clue about the risks of that. I'm sorry I can't be more help. Good luck and know that I'm cheering you on!